SIGN UP FOR NEWSLETTER

Signup for our newsletter to get notified about sales and new products

Upgrade your dental practice with our state-of-the-art 5-axis wet/dry dental milling machine.

Produce high-quality dental restorations with unparalleled precision and efficiency.

Streamline your milling process and increase productivity with our advanced features.

Invest in the future of your practice with our cutting-edge CAD CAM machine for dentistry today.

Large dimension equipment, contact sales to negotiate the door-to-door delivery solution.

Deal of the Day

Original price was: $90,000.00.$50,000.00Current price is: $50,000.00.

Want to buy even more quantity?

Wholesale Price Inquiry

The state-of-the-art 5-axis wet/dry dental milling machine is designed specifically for dental professionals seeking precision and efficiency in their practice.

Parameter:

| CNC controller | 5-axis dental system with touch screen | |

| Model | Dental Laboratorio-5T | |

| Milling mode | Dry/Wet | |

| Millable material | Titanium, Zirconia, Wax, PMMA, Chrom Cobalt, glass ceramics, E-Max, Peek | |

| Product Type | Crown/coping, Bridge, Inlay/Onlay, implant bar, abutment/abutment bridge, RPD, a full denture | |

| Spindle power | 2500W or 4000W | |

| Speed of spindle | 3000-60000rpm/min | |

| Spindle cooling | Water-cooled | |

| A/B axis motor | 100W with High precision slope gear reducer | |

| X/Y/Z axis motor | 400W servo motor | |

| Rotation range | A axis | ±360° |

| B axis | ±25° | |

| Attachable bur(tool) | shank diameter | 6mm |

| Length | 45mm | |

| Number of burs(Tools) housed | 30 pcs | |

| Tool change and check | Fully automatic | |

| Compatible compressed air | 0.6MPa | |

| Loadable workpiece shape | External Diameter | 98mm |

| Max Height | 25mm | |

| Min. Height | 10mm | |

| External dimensions | Length | 890mm |

| Weight(Depth) | 700mm | |

| Height | 1590mm | |

| Packing dimension | 1100*900*1800mm | |

| Net Weight | 400kg | |

| Gross weight | 450kg | |

| Input Voltage | Single-phase 220V 50Hz/60Hz | |

| Control command set | NC code | |

| Positioning accuracy | ±0.02mm | |

| Average milling time(dental crown) | Zirconia | 8-15 min |

| Wax | 3-6 min | |

| PMMA | 8-10 min | |

| Titanium | 10-15 min | |

Our machine is equipped with advanced features and benefits that make it the ideal choice for producing high-quality dental restorations.

This system allows for superior accuracy and flexibility in the milling process, ensuring that even the most intricate dental restorations are produced with ease. This level of precision guarantees a perfect fit and function every time.

Wet milling is ideal for processing materials such as glass ceramics, titanium & cobalt chrome, and pre-milled implant abutments. Meanwhile, dry milling is perfect for materials such as Peek, Zirconia, PMMA, and wax.

With an automated tool changer, our machine makes the integration of multiple tools and materials seamless, reducing the need for manual intervention and saving time, thus increasing productivity.

Our machine’s easy-to-use software, which is compatible with all open scanners (STL) and supports international ISO standard G code, makes it accessible to all dental professionals, regardless of their expertise level. Dentistry CAD and CAM are also fully supported.

Our machine is also built to perform. With a spindle speed of 3000-60000rpm/min and water-cooled spindle cooling, it is capable of handling any milling job with ease. The A/B axis motor, which features a high-precision slope gear reducer, is rated at 100W, while the X/Y/Z axis motor is a 400W servo motor. With a rotation range of A axis ±360° and B axis ±25°, the machine is capable of handling a wide variety of milling tasks.

The precision and accuracy of our milling machine are second to none. It is engineered to deliver precise and accurate milling results, ensuring that every restoration produced is of the highest possible standard. This level of precision is crucial for achieving optimal fit, function, and aesthetics in dental restorations.

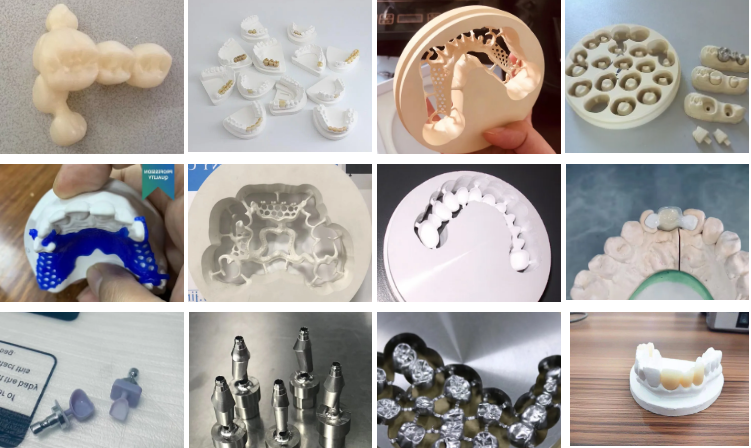

Milling restoration cases:

| Weight | 450 kg |

|---|---|

| Dimensions | 1800 × 1000 × 1900 cm |

Notifications