dental lab cad cam

Lithium Disilicate in Dentistry

Introduction

Lithium disilicate in dentistry is commonly known as glass ceramics used for tooth fillings. These glass-ceramics are aesthetic dental materials that are composed of SiO2-Al203-P2O5-ZRO2-K2O-Li2O glass systems. To form the glass-ceramic these glass systems are channeled via a solid-state reaction route.

Lithium disilicate in dentistry is used to restore damaged teeth or teeth. The particular reason for the circumstance is its strength and versatility, most of all its translucency. For this reason, lithium disilicate has the following benefits;

- It’s a better match to natural teeth due to its translucency

- It’s a process done quickly.

- Lithium disilicate materials last for a long.

Therefore because of lithium disilicate, one can have a doctor’s appointment to restore the tooth. Within hours a patient is fixed and goes home with a huge confident smile.

The lithium disilicate in dentistry system has attracted great attention since the development of the first glass-ceramic based on the stoichiometric composition of lithium disilicate. Dental Lithium disilicate is a new form and better way of technology that erases the idea of tooth plucking and introduces a new way of filling the tooth with unique yet special material. The idea of this material is to replace your old tooth with a new one, yet both are serving the same purpose and they take the same tooth structure. The material that is used for dental lithium is a glass-ceramic that includes lithium and silicon.

WHAT IS LITHIUM DISILICATE

Dental researchers have established a new way of fabricating fillings, crowns, and veneers by the ceramic material called lithium disilicate. This material of lithium disilicate in dentistry application has proved to be one of the best and common methods preferred by dental researchers due to its versatility and strength. The Lithium and Silicon are combined with other crystal-like elements to make anterior veneers. Anterior veneers are usually bonded over your natural tooth and do not require the removal of much tooth structure. Its production is very unique and delicate, it goes through the same manufacturing process as that in the glass technology which involves, melting, cooling, simultaneous nucleation of 2 different crystals, and growth of crystals. The lithium disilicate blocks are mostly blue, therefore to perfect the aesthetic feature of the tooth the polyvalent ions are inserted to give color to the lithium disilicate material. To ensure that the blocks are milled rightly, crystallization process at 840 ° C must be achieved successfully, this leads to the production of lithium metasilicate crystals, which are responsible for the materials processing properties and stability, however, it has to undergo a milling process which is the final stage, where the crystals gain their stability and strength.

CARING FOR YOUR LITHIUM DISILICATE RESTORATIONS

Lithium Disilicate in dentistry application is now available in every dental care facility as it’s made in the laboratories or chairside using the CAD/CAM technology. It is most preferred as it demonstrates a strength of 360 MPa and has a flexible nature of restoration by either adhesively bonded or conventionally cemented can be fabricated either in the laboratory or chairside using CAD/CAM Sirona Cerec MCXL Burs milling technology.

Steps to take when considering lithium disilicate

- The first step is to visit the dentist so that they can access the case or the problem at hand and clear you to proceed to the next step.

- Establish a treatment plan, after accessing the situation a solution is brought about

- Going through the clinical protocol clinical photographs, facebook bite records, polyvinyl siloxane (PVS) impressions, and a detailed laboratory prescription.

- AFTERCARE SERVICE

Taking care of the Lithium disilicate is key to maintain. Nothing unique or special is required just the normal of brushing your teeth at least twice a day and visiting the dentist annually to maintain that great smile.

Its highly advised to use teeth and gum defense Listerine anti-bacterial mouthwash, with added fluoride, which helps to kill germs that cause plaque, gingivitis, and bad breath; while strengthening teeth, increasing resistance to acid attacks, demineralization, and dental caries.

ADVANTAGE VENEER COSMETIC APPLICATION

- Aesthetic and Appealing Feature

This is one of its greatest features, it not only focuses on restructuring but on fixing your tooth to fit your structure and looks more appealing. It can be had to differentiate it from your natural teeth that is why it is an excellent option.

- Value for your Time

Unlike the past whereby it took time to receive the final restoration because you had to pass through the lab. Nowadays, this long procedure has been simplified, the crowns are invented at the dental care with the CAD/CAM machine, which carves the crown or filling from a solid dental cerec block of material.

- Long-lasting and Resistant

Research has proved that Lithium disilicate is very long-lasting and resistant, its survival rate is 94.8% after eight years for tooth-supported crowns and 100% after five years for implant-supported crowns. Also, it preserves its functionality features well, therefore reducing your frequent visits to the dentist as often.

- Versatility, strength, and translucency

Lithium disilicate materials portray a high edge strength and stability enabling it to adjust to its functionality steadily.

- Erases Traditional techniques

Traditional techniques have become vague and can no longer serve the purpose, however, these modern techniques are effective and efficient and solve the problem permanently.

Features of Lithium Disilicate

- Clinical indications and Performance

The materials are very adaptable and they contain good mechanical properties and favorable bonding strength to the dental tissues. They can also be utilized both for tooth and implant-supported restoration.

- Biocompatibility

It contains good quality soft tissue response which displays a very high level of biocompatibility due to the adhesion and production of the gingival fibroblasts especially when the surface is polished.

- Abrasiveness to Wear

It demonstrates some aggressive behavior that allows it to be durable and not wear easily, these features of disilicate lihtium in dentistry make it more adaptable and sustainable.

- Easily adjustable

It is kinder to one’s teeth since these crowns can be made thinner, therefore translates into less trauma in the tooth.

- More Resistance

Compared to monolithic lithium disilicate FDPs, monolithic zirconia FDPs, and lithium disilicate glass-ceramics pressed on zirconia-based FDPs showed superior fracture resistance while they manifested comparable fracture resistances.

Disadvantage

- A good quality product attracts costs, this is quite a disadvantage to the patient as they will have to chip in a huge cost to guarantee and get the process done. Also, the extra time needed in bonding might attract other costs.

- critical to adjust intraorally

- chipping of the veneering ceramics

- After a laboratory test was conducted it was noted that both wear volumes and friction coefficients of lithium disilicate were affected as the load increased rough surfaces, however, further research will be done to provide guidelines for better utilization and preparation of the material for long‐term success in dental restorations.

PHYSICAL PROPERTIES OF LITHIUM DISILICATE

- In vitro testing done has included testing of the strength by using a static load with a universal testing machine. After the tests were concluded the results revealed that;

- The lithium disilicate material has superior results compared to other dental materials used.

- The thickness of Lithium disilicate either minimum or maximum is a key criterion, especially when prospecting for success.

- The pressed lithium disilicate (IPS e.max Press LT and HT), strength is in the range of 360 MPa to 400 MPa .

CLINICAL PROPERTIES OF LITHIUM DISILICATE IN DENTISTRY

- The pressable lithium disilicate material is meant for inlays, outlays, thin veneers, veneers, partial crowns, anterior and posterior crowns, 3-unit anterior bridges, 3-unit premolar bridges, telescope primary crowns, and implant restorations.

- To facilitate a posterior crown fabrication to a full and required curve using the CAD methods, Lithium disilicate provides 360 MPa strength during the entire process of restoration. This enables restoration to bring out a monolithic strength.

- It is to the advantage of dentists and patients as it provides higher edge strength, the low viscosity of heated ingot which enables pressing to very thin dimension, and chameleon effect due to higher translucency.

FEATURE OF LITHIUM DISILICATE DENTAL CEREC BLOCK

- Good Mechanical Strength

It provides good mechanical strength by permitting the point bending strength to increase which is increased to 4+60Mpa, which provides a CAD system to design with higher accuracy that lessens processing trouble to ultra-thin veneer while boosting the strength and safety of materials seated in the mouth.

- Mimic the hardness of a natural tooth.

It is hard to differentiate it from the human teeth as they both seem similar in structure and functionality. The materials used are hard therefore reduces tear and wear of the tooth

- Overall fitness, easy to seat

It undergoes the crystallization process which allows stability as well as a good structural accuracy for milling restoration. This reduces the recurring seating and polishing process.

- More intuitive transparency aesthetics

As an all-ceramic material with a shrinkage ratio close to zero, it can provide a great convenience for efficient design and digital processing, and provide you with an idea and comfortable instant diagnosis and treatment experience combined with the rapid crystallization process.

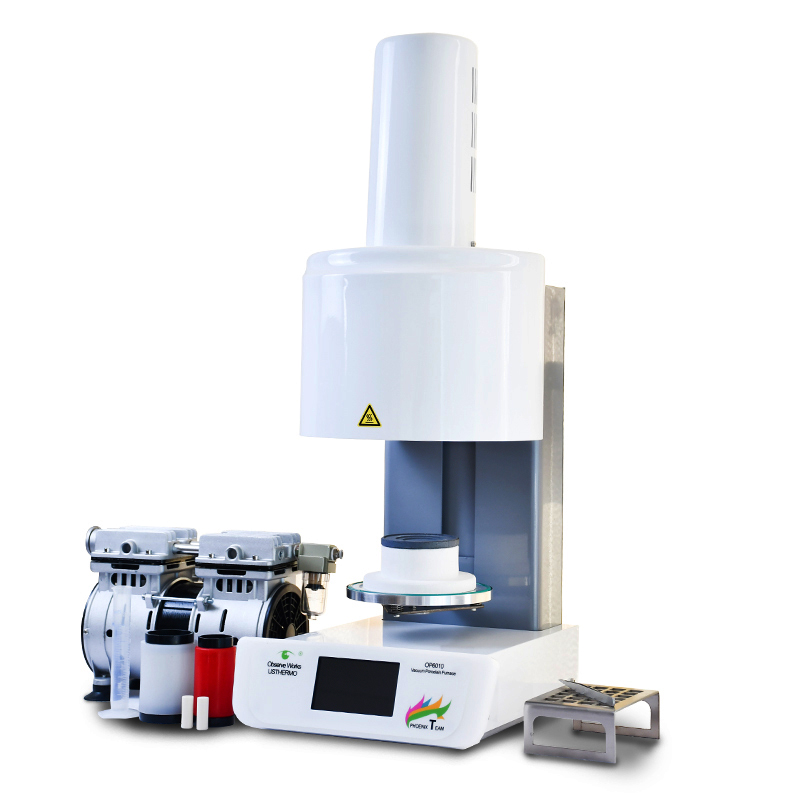

Optimizing Sintering for Lithium Disilicate Press Ingots in Wax-Lost Casting

For the wax-lost casting technology of lithium disilicate press ingots, a specialized furnace capable of reaching the material’s melting point is essential. This furnace must precisely control the temperature and atmosphere to ensure the ingots undergo optimal sintering, enhancing their mechanical properties and structural integrity. The process involves heating the ingots to their critical melting point, allowing for proper densification and crystallization, which are crucial for the final strength and durability of the dental restorations. Proper sintering conditions are vital to prevent defects and ensure the ingots meet the stringent requirements for dental applications.

Conclusion

Today, Lithium disilicate is one of the best restorative materials available for single unit indirect restorations. The Lithium disilicate material which includes; (IPS e.max Press and IPS e.max CAD [Ivoclar Vivadent]) has been in clinical trials for the last 4 years with adhesive and self-adhesive/conventional cementation, and the results have been very positive

Lithium disilicate technology has spread out to a wide range of people and has had quite a good review based on the performance and features. This special material has brought hope by creating a replica of the human tooth. The process of installation is quite easy and takes less amount of one time.

Lithium disilicate has continued developing is very strong, versatile, and representative of a human tooth. Its disilicate materials have maximized these benefits for laboratories and dentists. There is continuous laboratory research done to enhance the performance of its materials and maximize its use clinically.