dental laboratory material

Streamlining Your Dental Lab: A Guide to Dental Laboratorio’s Furnace Solutions

Dental laboratories play a crucial role in the creation of dental restorations, and dental furnaces are essential equipment in these labs. These furnaces are responsible for processing various materials, ensuring the production of high-quality, durable, and aesthetically pleasing restorations. In this blog post, we will discuss the importance of dental furnaces, the three primary materials used in dental laboratories, and how Dental Laboratorio’s comprehensive range of furnaces can help streamline your dental lab workflow.

The Three Primary Materials in Dental Laboratories:

- Zirconia: Known for its strength, biocompatibility, and natural appearance, zirconia is a popular material for dental restorations. Zirconia furnaces are designed to sinter zirconia restorations at high temperatures, typically around 1500°C, to achieve the desired physical properties and translucency.

- Porcelain Fused to Metal (PFM): PFM restorations combine the strength of a metal substructure with the aesthetics of porcelain. PFM furnaces are used to fuse the porcelain to the metal framework, requiring precise temperature control to ensure a strong bond and prevent cracking or chipping of the porcelain.

- Lithium Disilicate: This glass-ceramic material is known for its exceptional aesthetics and strength. Pressing furnaces are used to heat and press lithium disilicate ingots into the desired shape using a lost-wax technique. These furnaces must maintain accurate temperature control and pressure to ensure the proper flow and adaptation of the material.

Choosing the Right Furnace for Each Material:

Dental lab technicians must choose the appropriate furnace for each material to achieve the best possible results. Using the wrong furnace or incorrect settings can lead to subpar restorations, compromising both function and aesthetics. By understanding the unique requirements of each material and utilizing the correct furnaces, dental lab technicians can create high-quality restorations that meet the needs and expectations of both dentists and patients.

Dental Laboratorio’s Furnace Solutions:

Dental Laboratorio offers a comprehensive range of furnaces designed to cater to the unique needs of dental laboratories. With four distinct types of furnaces, our aim is to provide solutions for various dental restorations, ensuring optimal results and efficiency.

- Designed specifically for sintering zirconia restorations

- Supports user-defined programming settings, from normal to rapid speed sintering

- Maximum temperature setting of 1700℃

- Simple door opening and closing settings for easy sintering procedure

- Chamber supports up to 3 crucibles at a time

2,PFM Furnace:

- Specially designed for porcelain fused to metal restorations

- Supports user-defined programming settings

- Maximum temperature setting of 1200℃

- Utilizes a lifting table for sintering porcelain restorations

- Consists of two parts: furnace and vacuum pump

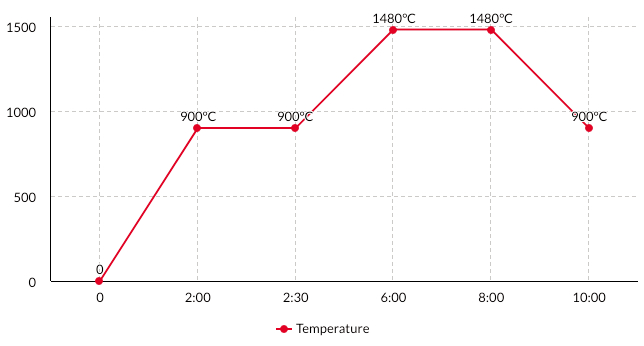

- Suitable for both lithium disilicate and PFM sintering restorations

- Lithium disilicate material has a melting point of approximately 1300°C

- Maximum temperature setting of 1200℃

- Comes in two parts: furnace and vacuum pump

4,Burnout Wax-Lost and 3D Metal Printing Furnace:

- Dual application furnace

- Burnout function for PFM and lithium disilicate press ingot investment model wax-lost procedure for casting

- Heat treatment for 3D-printed dental components, providing increased strength, hardness, corrosion resistance, and wear resistance

- Supports user-defined programming settings

- Lightweight and compact design, saving valuable lab space

By offering these four types of furnaces, Dental Laboratorio ensures that dental lab technicians have the right tools to create high-quality restorations using zirconia, PFM, and lithium disilicate materials. Our furnaces are designed to optimize the sintering and pressing processes, allowing for precise temperature control and customizable settings to suit the specific needs of each material and restoration type.

With Dental Laboratorio’s furnaces, dental laboratories can streamline their workflow, improve efficiency, and deliver exceptional results to their clients. Investing in the right dental furnace solutions will not only help you create superior dental restorations but also contribute to the overall success and growth of your dental laboratory.

-

Product on sale

All-In-One Vacuum Dental Furnace For Press Ingot And Porcelain Metal-fusedOriginal price was: $6,000.00.$5,399.00Current price is: $5,399.00.

All-In-One Vacuum Dental Furnace For Press Ingot And Porcelain Metal-fusedOriginal price was: $6,000.00.$5,399.00Current price is: $5,399.00. -

Product on sale

Dental Zirconia Sintering Furnace High-Capacity, Touchscreen, and Accurate Temperature ControlOriginal price was: $10,000.00.$6,266.00Current price is: $6,266.00.

Dental Zirconia Sintering Furnace High-Capacity, Touchscreen, and Accurate Temperature ControlOriginal price was: $10,000.00.$6,266.00Current price is: $6,266.00. -

Product on sale

Dental Porcelain FurnaceOriginal price was: $3,790.00.$3,150.00Current price is: $3,150.00.

Dental Porcelain FurnaceOriginal price was: $3,790.00.$3,150.00Current price is: $3,150.00. -

Product on sale

Dental Burnout Furnace For Press Ingot and MetalOriginal price was: $1,800.00.$1,279.00Current price is: $1,279.00.

Dental Burnout Furnace For Press Ingot and MetalOriginal price was: $1,800.00.$1,279.00Current price is: $1,279.00.